In the Knee Patch category, many products appear similar at first glance. However, experienced buyers and product managers understand that true quality differences are hidden beneath the surface—in the product structure, material balance, and production control.

For private-label brands aiming for long-term success, understanding what defines a professional, stable, and scalable Knee Patch is essential.

Product Structure Determines User Experience

A Knee Patch must adapt to a highly mobile body area. Unlike facial or small-area patches, the knee undergoes constant bending, stretching, and pressure during daily movement.

This creates several technical challenges:

-

Maintaining adhesion without restricting movement

-

Preserving elasticity without deformation

-

Ensuring consistent skin contact during prolonged wear

A well-designed Knee Patch balances flexibility, structural support, and skin comfort—a balance that cannot be achieved by material selection alone.

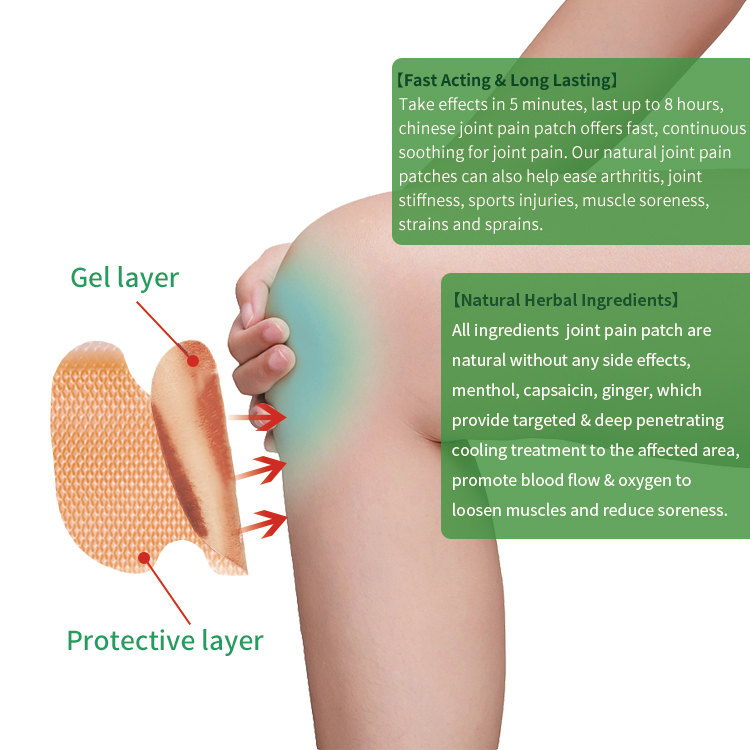

Why Hydrogel Technology Is Critical

Hydrogel-based Knee Patches have become the preferred structure for professional-grade products due to their unique physical properties. A properly formulated hydrogel offers:

-

High moisture retention for prolonged comfort

-

Natural flexibility that follows joint movement

-

Gentle adhesion without aggressive stickiness

However, hydrogel performance depends heavily on formulation precision. Small deviations in water content, polymer ratios, or crosslink density can significantly affect texture, cooling behavior, and durability.

Thickness, Elasticity, and Stability Must Be Balanced

One common misconception is that thicker patches provide better performance. In reality, excessive thickness may reduce comfort and increase movement resistance, while overly thin patches may lack durability.

Professional Knee Patch design requires:

-

Optimized thickness for joint flexibility

-

Controlled elasticity to prevent tearing or sliding

-

Structural stability throughout the wear cycle

These factors must remain consistent across production batches to ensure uniform market experience.

Performance Consistency Defines Brand Credibility

From a market perspective, inconsistency is one of the fastest ways to lose consumer trust. If knee patches perform differently between batches, users quickly notice.

This is why experienced OEM manufacturers emphasize:

-

Standardized production parameters

-

In-process quality control

-

Batch-to-batch performance verification

Consistency is not a marketing feature—it is the foundation of repeat sales.

Manufacturing Experience Behind Technical Stability

While many suppliers can produce sample knee patches, far fewer can maintain quality at scale. Large-volume production introduces challenges in coating uniformity, curing time, and environmental control.

OEM partners with long-term hydrogel manufacturing experience are better equipped to manage these variables and deliver stable results across large orders.

Conclusion

A professional Knee Patch is defined not by appearance, but by structural balance, hydrogel formulation precision, and production consistency. Brands that understand these technical fundamentals are better positioned to select reliable OEM partners and build sustainable joint care product lines.

Biours Biosciences Co., Ltd.

Biours Biosciences Co., Ltd.