At first glance, many heat therapy pain relief patches look almost identical: similar size, comparable packaging, and overlapping functional claims. 然而, consumer experiences can vary dramatically. Some patches adhere comfortably and provide stable heat, while others shift, peel, or deliver uneven warmth.

These differences are not accidental—they stem from product structure and technical design. For brands and project managers evaluating OEM partners, understanding these technical differences is critical to selecting products suitable for long-term market success.

Consistent Heat Is More Important Than Intensity

Professional patch design does not aim for immediate high heat; it emphasizes gradual, sustained warmth. Excessive initial heat can cause discomfort, discouraging repeat use.

Well-designed heat therapy patches employ controlled heating systems to release warmth over time, creating a comfortable, stable thermal experience. This consistency is key to consumer acceptance and encourages repeat purchases.

Adhesion and Fit Determine Usage Experience

As a skin-contact product, patch adhesion is a major factor. Poorly designed patches can peel or shift, reducing heat efficiency and causing a noticeable foreign-body sensation.

Technical design considerations include:

-

Base material elasticity

-

Patch thickness and flexibility

-

Surface adhesion patterns

High-quality design ensures the patch maintains intimate skin contact, even during movement, enhancing overall comfort.

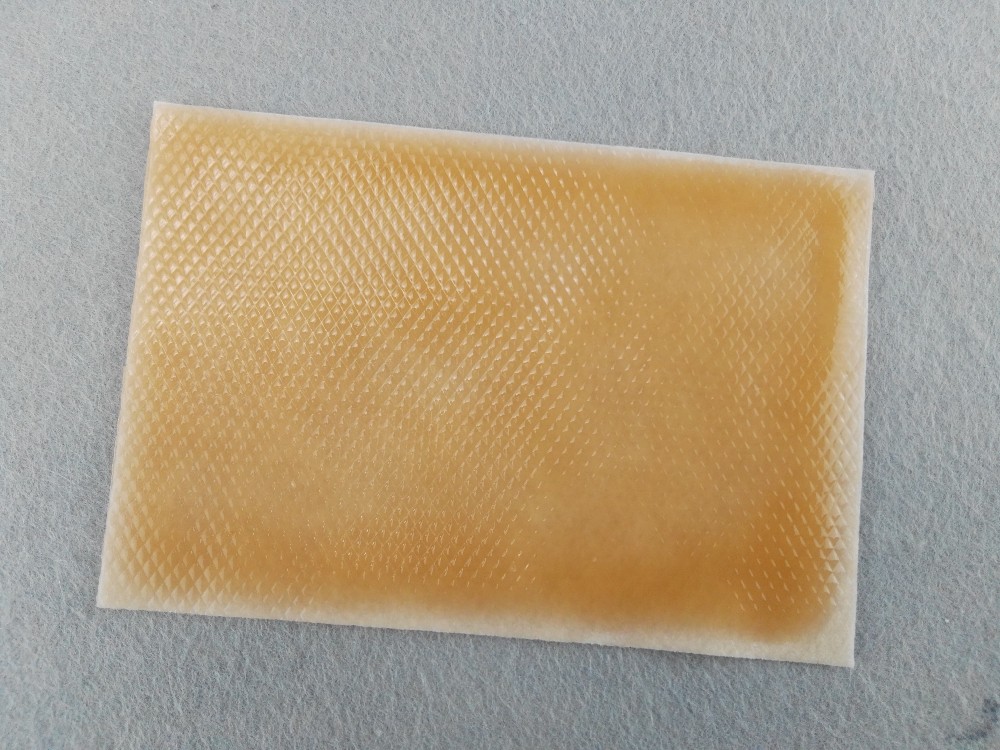

Hydrogel Structure Enhances Comfort and Stability

Many heat therapy patches incorporate hydrogel or composite hydrogel carriers. Hydrogel plays a critical role in cushioning, heat conduction, and overall tactile experience.

A stable hydrogel formulation maintains softness and shape throughout wear, even under thermal stress. This is why visually identical patches can deliver entirely different user experiences.

Heat Distribution Relies on Structural Design

Uneven heat is another common problem. If the internal structure is poorly engineered, some areas may become too hot while others remain cool, diminishing therapeutic effect.

Professional designs integrate heating elements and hydrogel layers to achieve uniform warmth across the applied area. Achieving this requires rigorous R&D and production validation.

Production Stability Determines Scalability

对于品牌而言, a patch performing well in small batches does not guarantee success. Truly market-ready heat therapy patches maintain consistent performance across large-scale production.

A mature structure ensures:

-

Batch-to-batch consistency

-

Reduced customer complaints

-

Predictable shelf life

This reliability is especially crucial for overseas brands managing multiple markets.

结论

The professionalism of heat therapy pain relief patches lies not in surface claims but in hidden structural and technical details. Understanding these differences helps brands evaluate whether a product is suitable for long-term, repeatable sales, and indirectly reflects the technical competence of OEM partners.

Biours Biosciences Co.(比尔斯生物科学公司), 有限公司.

Biours Biosciences Co.(比尔斯生物科学公司), 有限公司.