在 膝盖贴片 类别中, 许多产品乍一看相似. 然而, 有经验的买家和产品经理都明白, 真正的质量差异隐藏在表面之下—在产品结构、, 材料平衡、, 以及生产控制中.

对于旨在长期成功的自有品牌来说,, 理解什么定义了一个 专业的、, 稳定的、, 可扩展的膝盖贴 非常重要.

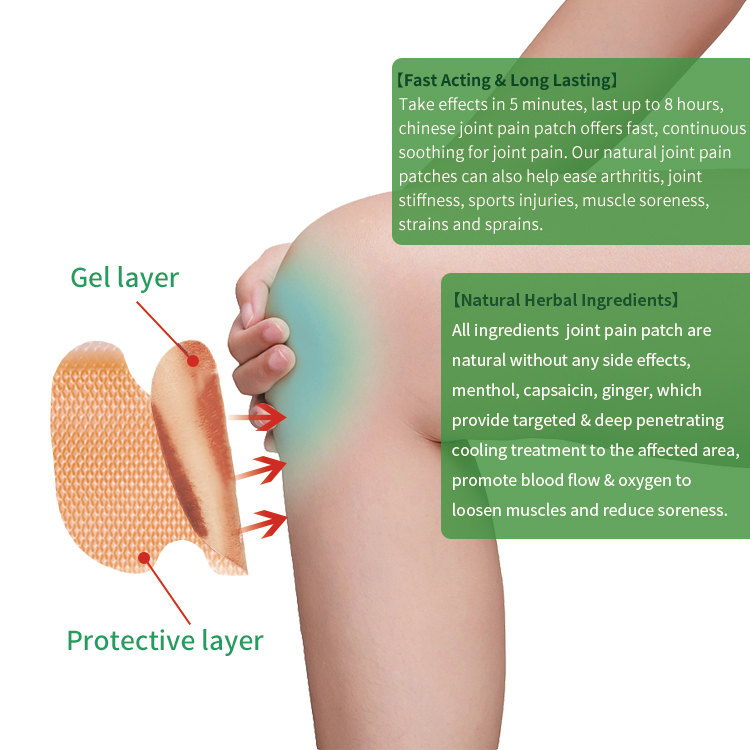

产品结构决定用户体验

膝盖贴必须适应高度活动的身体部位. 与面部或小面积贴片不同,, 膝盖在日常活动中会不断弯曲、, 伸展、, 承受压力.

这带来了若干技术挑战:

-

在不限制运动的情况下维持粘附力

-

保持弹性而不变形

-

Ensuring consistent skin contact during prolonged wear

A well-designed Knee Patch balances flexibility, structural support, and skin comfort—a balance that cannot be achieved by material selection alone.

Why Hydrogel Technology Is Critical

Hydrogel-based Knee Patches have become the preferred structure for professional-grade products due to their unique physical properties. A properly formulated hydrogel offers:

-

High moisture retention for prolonged comfort

-

Natural flexibility that follows joint movement

-

Gentle adhesion without aggressive stickiness

然而, hydrogel performance depends heavily on formulation precision. Small deviations in water content, polymer ratios, or crosslink density can significantly affect texture, cooling behavior, and durability.

Thickness, Elasticity, and Stability Must Be Balanced

One common misconception is that thicker patches provide better performance. In reality, excessive thickness may reduce comfort and increase movement resistance, while overly thin patches may lack durability.

Professional Knee Patch design requires:

-

Optimized thickness for joint flexibility

-

Controlled elasticity to prevent tearing or sliding

-

Structural stability throughout the wear cycle

These factors must remain consistent across production batches to ensure uniform market experience.

Performance Consistency Defines Brand Credibility

From a market perspective, inconsistency is one of the fastest ways to lose consumer trust. If knee patches perform differently between batches, users quickly notice.

This is why experienced OEM manufacturers emphasize:

-

Standardized production parameters

-

In-process quality control

-

Batch-to-batch performance verification

Consistency is not a marketing feature—it is the foundation of repeat sales.

Manufacturing Experience Behind Technical Stability

While many suppliers can produce sample knee patches, far fewer can maintain quality at scale. Large-volume production introduces challenges in coating uniformity, curing time, and environmental control.

OEM partners with long-term hydrogel manufacturing experience are better equipped to manage these variables and deliver stable results across large orders.

结论

A professional Knee Patch is defined not by appearance, 而是由 structural balance, hydrogel formulation precision, and production consistency. Brands that understand these technical fundamentals are better positioned to select reliable OEM partners and build sustainable joint care product lines.

Biours Biosciences Co.(比尔斯生物科学公司), 有限公司.

Biours Biosciences Co.(比尔斯生物科学公司), 有限公司.