For brands entering or expanding within the cooling gel sheet category, OEM selection is not simply a procurement decision—it is a strategic partnership choice that affects product stability, supply reliability, and long-term brand reputation.

Consistency Is the Core OEM Value

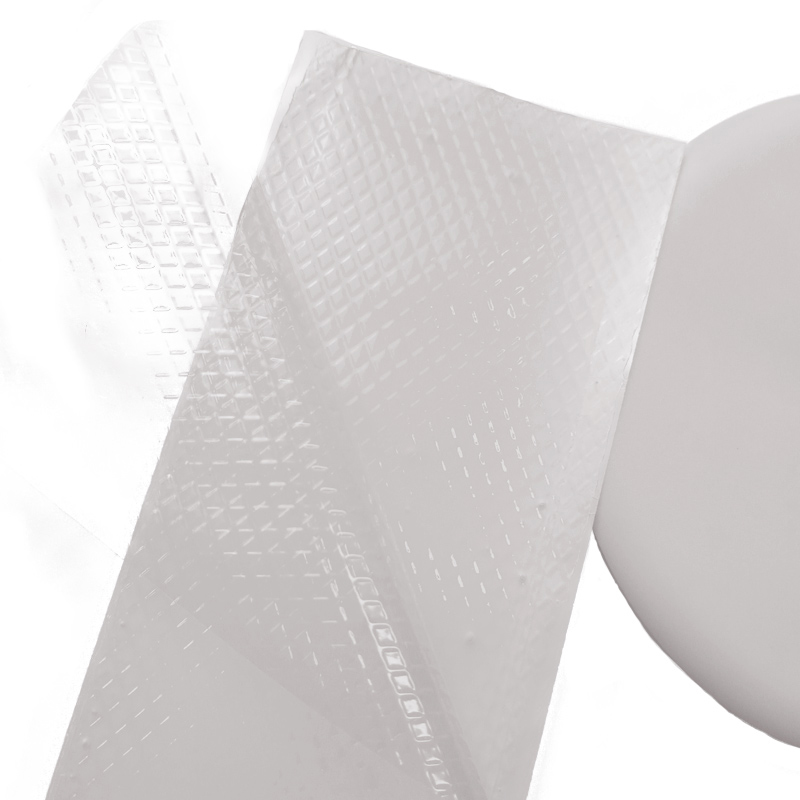

Transparent cooling gel sheets rely heavily on hydrogel formulation balance. Small deviations in water content, polymer ratios, or cooling agents can significantly affect:

-

Cooling duration

-

Adhesion stability

-

Skin comfort

An experienced OEM manufacturer maintains strict formulation control to ensure batch-to-batch consistency, which is critical for maintaining brand credibility.

Scalable Production Without Quality Trade-Offs

По мере роста спроса, production scalability becomes a decisive factor. Квалифицированные OEM-заводы способны масштабировать производство, сохраняя при этом структурную целостность и точность упаковки.

Эта возможность позволяет брендам быстро реагировать на рост рынка без колебаний качества или задержек в доставке.

Регулирование & Поддержка документации

Профессиональные OEM-партнёры предоставляют:

-

Прозрачность ингредиентов

-

Записи о контроле качества

-

Документы о соблюдении требований

Эти элементы имеют ключевое значение для брендов, которые ориентируются на международные регуляторные проверки и требования дистрибьюторов.

Поддержка долгосрочного развития

Кроме первоначального производства, надёжные OEM-партнёры поддерживают:

-

Оптимизацию упаковки

-

Улучшение структуры затрат

-

Модернизацию продукции и расширение линейки

Это снижает риск будущей разработки и сокращает время выхода на рынок новых SKU.

Резюме

Выбор правильного OEM-производителя прозрачных охлаждающих гелевых листов не сводится к краткосрочной экономии — речь идёт о обеспечении долгосрочная стабильность, масштабируемость, и доверие к бренду. Надежный OEM-партнер становится продолжением стратегии цепочки поставок бренда, а не просто поставщиком.

Биурс Биосайенс Ко., ООО.

Биурс Биосайенс Ко., ООО.