In the body care patch market, leg relief patches may appear to be a mature and common category. No entanto, in actual OEM production, their structural design and quality control directly determine whether the product can maintain long-term market viability. For brands focused on export and private label production, the question is not whether leg relief patches can be produced, but whether they can be produced consistently and reliably over time.

Unlike small-area patches for eyes or other localized regions, the leg area experiences greater movement and skin tension variations, which places higher demands on patch design. If the patch structure is not properly engineered, issues such as edge lifting, slippage, or poor adhesion can easily occur during use, negatively affecting the consumer’s perception of product quality.

Structural Challenges for Leg Patches

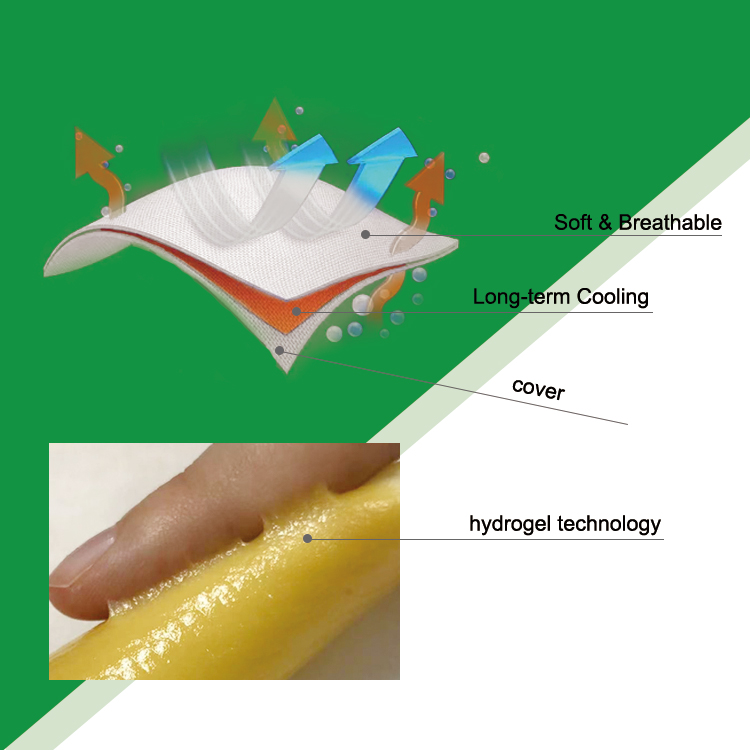

From an anatomical perspective, leg skin frequently stretches and contracts during daily activities. This means the patch must possess good elasticity and recovery. If the material is too stiff, it can feel uncomfortable; if too soft, it may lose support during use.

Portanto, mature leg relief patches carefully balance patch thickness, conteúdo de água, and substrate elasticity. Particularly when using hydrogel or composite hydrogel carriers, it is essential to maintain soft touch and comfort during application while ensuring structural stability over long periods of wear.

Achieving this structural balance cannot be done with a single trial. OEM factories must optimize parameters through repeated production iterations para criar uma solução de produto estável e fiável.

Importância da Estabilidade Estrutural para Produção em Massa

Do ponto de vista de um OEM, as almofadas de alívio para as pernas estruturalmente estáveis são mais fáceis de produzir em grande escala. A estabilidade garante que durante processos como corte, laminação, e embalagens, o produto não se deforma, rasga-se, ou não adere corretamente.

Para clientes de marca, a consistência dos lotes é a base da confiança no mercado. Se o mesmo produto variar de forma notável entre lotes, isso aumenta a pressão pós-venda e diminui a confiança dos consumidores na marca. Almofadas de alívio para as pernas maduras podem manter uma aparência consistente e experiência de utilização em produção em larga escala, garantindo um desempenho de vendas fiável.

Impacto da Experiência da Fábrica OEM

Embora as almofadas de alívio para pernas não sejam produtos de grande complexidade, a sua produção requer uma experiência significativa da fábrica. For hydrogel-based systems, controlling water content, o desempenho de adesão, and final product stability directly affects quality.

Fábricas OEM com long-term hydrogel R&experiência em I&D e produção can enhance stability during transportation and storage without compromising user comfort. This capability is especially valuable for cross-border clients and export-oriented brands.

Long-Term Value for Brand Cooperation

From a brand management perspective, choosing leg relief patches with mature structure and stable production supports long-term supply relationships. Products do not require frequent structural adjustments or mold changes, reducing development costs and shortening time-to-market for new products.

Such products are ideal as core SKUs in a body care line, providing stable sales while laying the groundwork for future upgrades and product series expansion.

Conclusão

No geral, leg relief patches in OEM production are more than simple patch products. Their structural design and quality stability directly influence a brand’s ability to achieve sustainable, long-term market presence. Selecting an OEM factory with mature hydrogel expertise and reliable production capacity is crucial for ensuring successful product launch and ongoing operations.

Biours Biosciences Co., Ltd.

Biours Biosciences Co., Ltd.